Moscow — The top submarine maker in Russia said that it has finished extensively modernizing its electroplating factory, which is in charge of covering metallic objects with a specific substance.

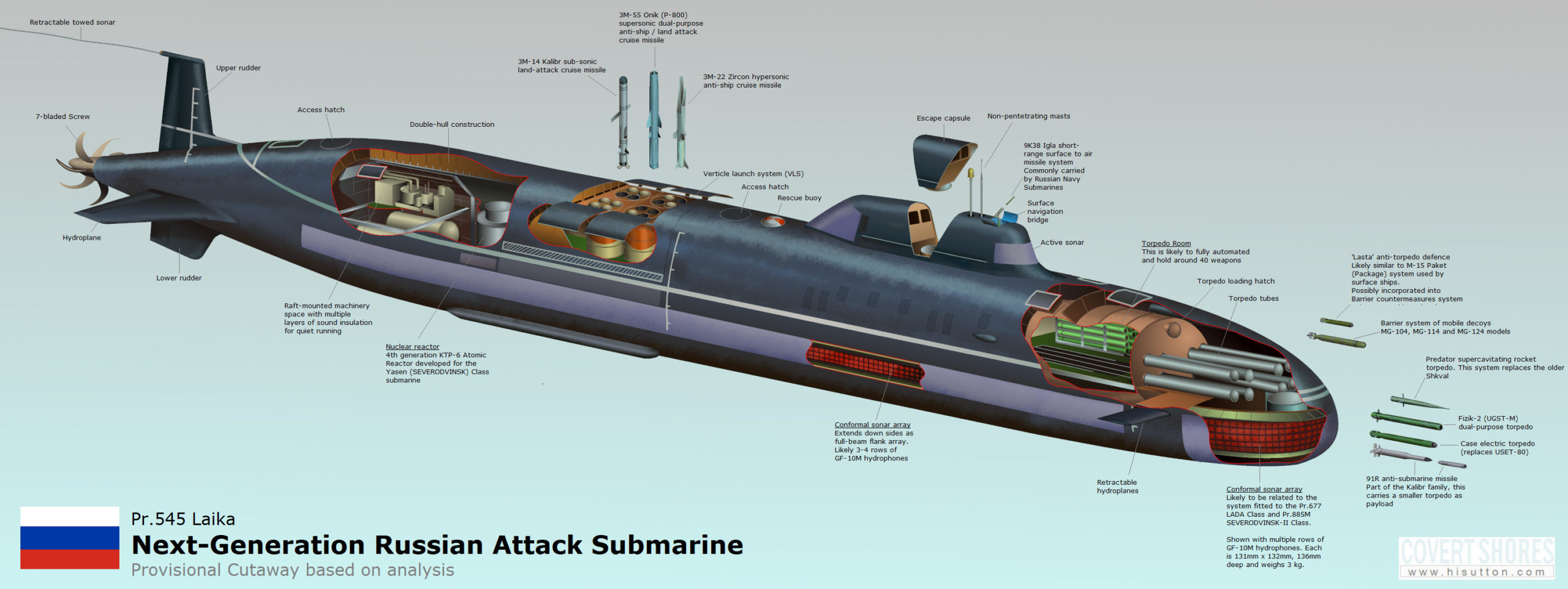

The goal of the project, which ended last month, was to improve Sevmash’s energy efficiency in order to facilitate the construction of a fifth-generation nuclear submarine for Russia.

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/archetype/NDBHPA247ZCG7M67RVXVUNZIZU.jpg)

According to the corporation, the shipbuilder has started running electroplating facilities with an emphasis on chemical nickel plating, solid and electrical insulating anodizing, ultrasonic cleaning, and special chrome plating.

Sevmash appears to have achieved a very consistent rate of submarine production by the start of the 2010s–2020s. According to Pavel Luzin, a military analyst at the Center for European Policy Analysis in Washington, D.C., the cycle of development and testing currently takes around seven years, Defense news said. The facility is simultaneously constructing eight to ten submarines at various levels of development. To improve its business efficiency, Sevmash is building a new production plant.

Luzin continued, “It’s still unclear whether things will work out as planned for the shipbuilder.”

“It is hard to predict how effective the modernization of Sevmash will be, given the closure of access to Western technologies and equipment, when the entire chain of cooperation involved in the creation of submarines suffers from sanctions,” the speaker stated.

Sevmash’s industrial facilities underwent their most recent significant overhaul in the 1970s in preparation for the building of third-generation nuclear submarines. Sevmash started retooling and rebuilding in 2011 as a result of its involvement in the government’s Federal Target Program, which aims to enhance Russia’s military-industrial complex.

Sevmash was supposed to get 46.5 billion rubles (about $507 million) under the program. Prior to 2017, the primary costs were associated with the acquisition of automated technology tools, multichannel measurement devices, computer-controlled, high-precision machinery, and energy and mechanized equipment with high efficiency. These were purchased by the corporation from Germany, the Czech Republic, France, Switzerland, and Italy.

Sevmash purchased equipment and machinery both locally and from Belarus after 2022. For instance, in February 2024, it paid 1.5 billion rubles to the Krylov State Research Center for technological equipment for a deperming demagnetization station.

Sevmash will stay in the Federal Target Program through 2027, although it has to use this time to update its manufacturing facilities in order to build a fifth-generation nuclear submarine.

According to Luzin, this endeavor is already underway, and considering that the Borei and Yasen submarines will not be finished building until the early 2030s, “Russia is in a hurry to create fifth-generation submarines.”

The company started building a floating dock in 2020 to replace its current Sukhona port, which was constructed more than 40 years ago. Sevmash finished converting the equipment from oil and coal to natural gas, which is more cost-effective and energy-efficient, two years later. It finished rebuilding its industrial embankments in shallow and deep water, crossing docks, and discharging berth that same year.

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/archetype/B7XVXIHJ3VEPNHWAEWHMSC4QAY.jpg)

The business also completed the upgrade of its steel workshop in 2023, during which it purchased closed water circulation cooling systems, gas treatment stations for furnace emissions, electric arc furnaces for producing steel, and equipment for secondary steel treatment. Sevmash stated that the objective here was to enhance the cost-effectiveness of materials and resources and more efficiently arrange tasks involving the foundry.

The business is modernizing its crane fleet. About 300 parts have already been changed, including the cranes themselves, manipulators, and elevators. The plant’s parent business, United Shipbuilding Corp., anticipates that the project will be finished by 2027.

Sevmash is also upgrading its forging and heating workshop, which is used to heat-treat parts for upcoming nuclear submarines, according to the facility. There, dozens of brand-new electric furnaces and other appliances are being installed, according to the statement. It has been over 60 years since the workshop’s equipment was replaced on this scale.

Additionally, the shipyard is modernizing its welding apparatus. Despite an unsuccessful attempt to purchase welding replacement parts from the Swedish business ESAB that year, Sevmash spent around 25 million rubles on welding equipment in 2022, according to Russia’s official procurement website.

636 different pieces of equipment were placed into service just last year, according to Sevmash. A brand-new central digital automated phone exchange was one of them. Additionally, the factory has announced that it is buying transport cars.

The establishment of the infrastructure required for the use of the block-modular technique of nuclear submarine building is another significant aspect of the plant’s technological re-equipment. That method entails putting together submarines from sizable equipment-filled chunks. It would take the place of Sevmash’s present modular-aggregate approach, which was developed during the building of third-generation nuclear submarines.

Under the new arrangement, the majority of the assembly is completed in dedicated workshops prior to the blocks being sent to the slipway for the submarine’s final assembly. Sevmash claims that this method will decrease the time needed to build a submarine by 18 months, increase work quality, and lower labor intensity and manufacturing costs.

The business would need to construct integrated cleaning and painting chambers, enlarge its assembly and welding workshops, and retool for so-called buildingway-delivery manufacturing in order to enable block production. It is anticipated that this work would end in 2031.

“For more than a year, the block construction method has been developed for submarines. It necessitates greater accuracy throughout the entire technological process and a high-production culture throughout.” Because it needs the permission of USC, Rosatom, and other collaboration partners, its effective implementation is still up in the air, according to Luzin.